Professional Plastic Injection Mold Factory for Coffee Machines

Coffee machines have become an essential part of modern life, providing coffee enthusiasts with the perfect cup of their favorite brew at the touch of a button. Behind the seamless operation and flawless design of these coffee machines lies a crucial component: the plastic injection molds that shape various parts of the machine. In this article, we will delve into the significance of a plastic mold maker in the coffee machine industry and explore the essential aspects of their work.

The Role of a Plastic Mold Maker:

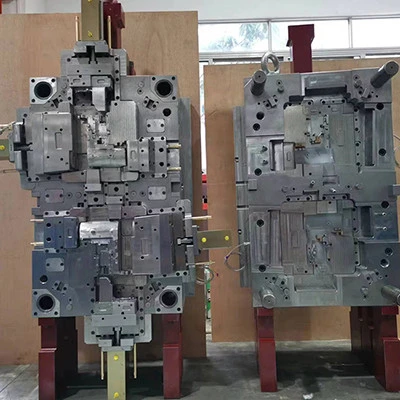

A plastic mould maker plays a pivotal role in the production of coffee machines. They are the craftsmen who design and fabricate the injection molds, which are crucial tools used to shape plastic components. These molds are responsible for creating parts such as the water tank, handle, lid, outer shell, coffee powder housing, control buttons, filter, motor gear housing, and other exterior components that come together to form a functional coffee machine.

Importance of Material Selection:

One of the most critical considerations in the production of coffee machine parts is the choice of plastic materials. Since these components come into contact with food and beverages, it is imperative to use food-grade materials. Commonly used food-grade plastics include ABS, PP, transparent SAN, and TRITAN. Each material offers specific properties that make it suitable for various parts of the coffee machine. The plastic mold maker works closely with the coffee machine manufacturer to propose the most appropriate materials based on the functional requirements of each part.

Mold Steel Selection for Longevity:

Another crucial aspect of plastic mold making is selecting the appropriate mold steel. The mold's life refers to the total number of products that a set of molds can produce before requiring replacement. Typically, mold makers categorize mold life into different levels, such as an experimental level of 30,000 shots, small production molds capable of producing 100,000 units, and large-scale series production molds with capacities of 500,000 to 1 million units. The choice of mold steel depends on the desired mold life and the expected production volume of the coffee machine.

Quality Assurance and HanKing's Commitment:

Quality assurance is of utmost importance in the plastic injection mold industry. Customers rely on the mold maker's ability to deliver molds that meet the agreed-upon specifications and mold life. In the case of HanKing, they guarantee achieving the specified mold life for their coffee machine molds. Additionally, they take responsibility for maintenance, ensuring that the molds continue to perform optimally throughout their lifespan.

The Advantages of HanKing as an Injection Mold Factory:

HanKing stands out in the industry with its strengths and capabilities. Our plastic injection mold design team comprises experienced professionals with vast expertise in the field. Working alongside them are senior engineers and a dedicated project management team, ensuring that every aspect of mold production is carefully planned and executed. With years of experience as a tooling maker, HanKing has honed its skills to deliver high-quality molds for the coffee machine industry.

Comprehensive Facilities for Mold Production:

As a reputable injection mold factory, HanKing is well-equipped with cutting-edge tooling making equipment in its plastic tooling shop. This ensures that the molds are fabricated with precision and accuracy, meeting the exact specifications required for the coffee machine parts. Moreover, their injection molding shop boasts 17 injection machines, allowing for efficient and timely production of the molded components.

In conclusion, the significance of a plastic mold maker in the coffee machine industry cannot be overstated. Our expertise in designing and fabricating injection molds is instrumental in shaping the various components that make up a functional coffee machine. From material selection to mold steel choice, every decision made by the mold maker impacts the quality and longevity of the final product. HanKing, as a professional plastic injection mold making factory, exemplifies these traits, boasting a strong design team, experienced engineers, and state-of-the-art facilities. Our commitment to quality assurance and customer satisfaction sets us apart as a trusted partner in the plastic injection mold manufacturing process.

English

English Deutsch

Deutsch italiano

italiano русский

русский français

français română

română العربية

العربية Español

Español Polska

Polska 日本語

日本語 한국어

한국어

Запрос

Запрос

Позвоните нам на:

Позвоните нам на:  Напишите нам:

Напишите нам:  No 4, BeiQu Road, ChenCun village, Humen town, Dongguan City, Guangdong Province, China.

No 4, BeiQu Road, ChenCun village, Humen town, Dongguan City, Guangdong Province, China.